Our group dives deep* into surfaces and interfaces of energy materials identifying the relationships between material chemical composition, structure and morphology, and material properties and device performance. To do this, we rely on multi-technique, multi-scale analysis, as well as in situ and in operando studies. Projects and proposals change over time as questions are answered, new questions emerge, and priorities evolve. But in the long run, our groups’ activities are consistently working toward three main themes; those and our current projects can be found below.

*sometimes only a few nm deep

*sometimes only a few nm deep

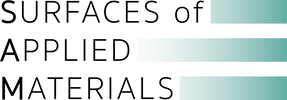

Fundamental physico-chemical interactions of applied materialsAs new materials are constantly developed for use in fuel cells, batteries, electrolyzers and other energy applications, characterization plays a crucial role in moving a novel material from the lab bench to the real world. Generally, the chemistry that makes an energy material useful occurs at either its surface or the interface between one material and another. Understanding that chemistry (and sometimes physics, too) on a fundamental level can tell us what property of a new material is actually doing the important work, whether or not there are properties that are contributing to decreased utility, and how to optimize the material for better performance. These studies form a puzzle where you are putting many different types of pieces together in order to see the final picture clearly -, and they quite often require technique development to push the limits of characterization. For example, see Mike’s project about in-situ XPS studies of the fundamental interactions between a solid catalyst material and gaseous reactants.

|

Multi-scale multi-technique characterization of surfaces and interfacesEvery technique has its limitations and advantages; similarly, some information is easier to collect at smaller or larger scales. Therefore, a carefully designed experiment and well-considered analysis can stitch together the data from multiple techniques to paint a picture of a material or device from the nano-scale to the macro-scale (think of starting with a 2D, 10 piece puzzle that suddenly turns into a 3D 1000 piece puzzle). In surface science specifically, different techniques can vary in terms of surface-sensitivity, or in terms of chemical versus structural information. A great example of such a multi-technique approach is Sarah’s work on platinum and iridium-based catalysts for use in fuel cells and electrolyzers.

|

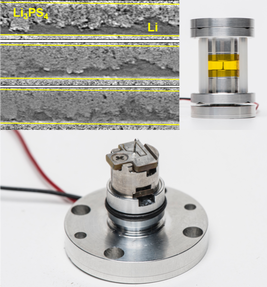

In situ and Operando evolution of interfaces for energy devicesOnce applied materials are assembled into devices, understanding how and why each surface and interface is contributing to device performance can be complicated. Therefore, it’s often useful to apply the chosen characterization technique while the device is operating (in-operando) and watch as it changes over time. This helps to isolate the interactions that are relevant to the devices’ functionality. Device-scale characterization of surfaces and interfaces requires creative experimental designs and a lot of experiments to ensure all possible contributing factors are identified and resolved. These types of experiments usually end up with a lot of data analysis! Think of trying to characterize the bread/jelly interface in a peanut butter and jelly sandwich while the sandwich is being toasted, or, like in Natalie’s project, the lithium anode/ceramic electrolyte interface in a solid-state battery while the battery is cycling.

|